Detailed description:

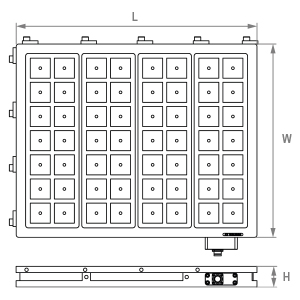

The Mastermill electropermanent magnetic chuck is a chuck with 50×50 mm square poles, a compact low design (only 51 mm high) and a nominal holding force of 170 N/cm2. The electromagnet has a practical offset (slot) around its entire perimeter for clamps and there is also enough space on the magnet to perform through clamping holes.

The standard delivery includes magnet with a quick “bayonet” coupling connector, stop blocks on 2 sides, and with a 6 metre-long armoured cable.

Important parameters:

- Application: Milling

- Technology: Electropermanent

- Holding force: 170 N/cm2

- Min. workpiece size: 50 x 110 x 20 mm

- Poles: Square

- Regrinding limit: 6 mm

- Pole size: 50 x 50 mm

- Top plate: steel/stainless steel combination

- Guarantee: 2 years

Additional information:

Beyond the standard design, the customer can choose:

- different cable outlet location parts

- through going holes for fastening the magnet to the table

- a top plate with a corrosion resistant gaps between the poles

If you have any questions about the arrangement of the chuck or about the selection of a suitable control unit, contact us. We will be happy to advise you.

Use:

- Machining of uneven parts up to 5 sides

- Clamping of a wide range of workpiece sizes during milling

- Clamping of large forms, castings, blocks, structures, etc.during drilling operations

- Rough grinding of large parts

Scope of supply:

- Magnetic chuck

- Side stop blocks

- Armoured power supply cable

- Certificate

- Instructions for use

Parameters:

| Model |

Number of poles |

W (mm) |

L (mm) |

H (mm) |

Weight (kg) |

| MM50300490 |

24 |

300 |

490 |

51 |

49 |

| MM50300600 |

32 |

300 |

600 |

51 |

61 |

| MM50300800 |

40 |

300 |

800 |

51 |

82 |

| MM50300900 |

48 |

300 |

900 |

51 |

92 |

| MM50420490 |

36 |

420 |

490 |

51 |

70 |

| MM50420600 |

48 |

420 |

600 |

51 |

86 |

| MM50420800 |

60 |

420 |

800 |

51 |

114 |

| MM50420900 |

72 |

420 |

900 |

51 |

128 |

| MM50480600 |

56 |

480 |

600 |

51 |

97 |

| MM50480800 |

70 |

480 |

800 |

51 |

130 |

| MM50480900 |

84 |

480 |

900 |

51 |

146 |

| MM50480990 |

84 |

480 |

990 |

51 |

161 |

| MM50580800 |

80 |

580 |

800 |

51 |

157 |

| MM50580900 |

96 |

580 |

900 |

51 |

177 |

| MM50850990 |

96 |

580 |

990 |

51 |

194 |