Detailed description:

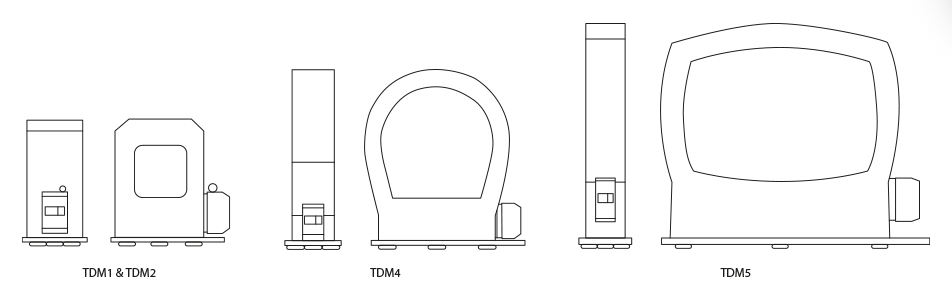

The TDM tunnel demagnetizer is designed for

continuous operation. It is used for the elimination of residual magnetism in series produced workpieces and/or components such as moulds, bearings, and component parts in automated production plants.

The tunnel demagnetizer operates on the principle of a gradually weakening alternating current, which eliminates the magnetism to a certain depth. For optimum performance, it is

necessary to select a suitable dimension so that the workpieces are in as close as possible contact with the aperture of the device.

Important parameters:

- Application: Electro

- Technology: Demagnetization

- Duty cycle: 100 %

- Power: 230 / 400 VAC (optionally)

- Guarantee: 2 years

Additional information:

We will deliver the tunnel demagnetizer, including a customized conveyor belt by request. For this option, please contact us.

Use:

- Demagnetization of large components, workpieces, and component parts of various shapes

- Suitable for continuous operation

Scope of supply:

- Demagnetizer

- Instructions for use

Parameters

| Model |

Aperture (mm) |

Power supply (VAC/Hz) |

| TDM5400 |

600 x 420 |

400/50 |

| TDM4400 |

450 x 450 |

400/50 |

| TDM2230 |

255 x 255 |

230/50 |

TDM2400 |

255 x 255 |

400/50 |

TDM1230 |

180 x 180 |

230/50 |

TDM1400 |

180 x 180 |

400/50 |