Detailed description:

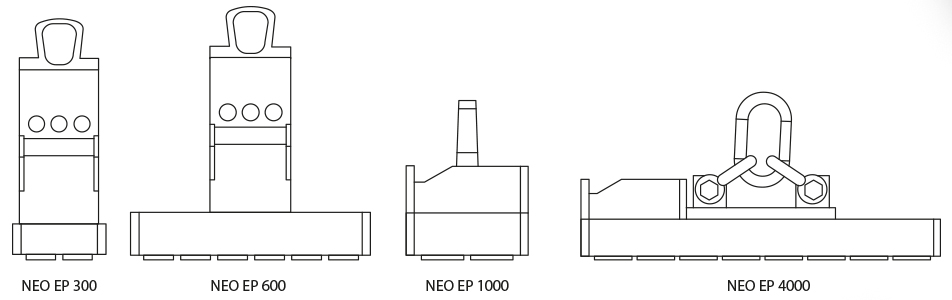

Neo EP electropermanent lifting magnets are a professional solution to frequent handling. It does not require much effort to install. You can easily connect it to the ordinary power supply using the supplied power cable. After electric activation, the load is held by permanent lifting magnets, without the need of subsequent power supply. Electric control with buttons allows the operator to activate the device without physical effort. Due to the optional remote control, this is also possible in locations with poor accessibility.

Neo EP can be controlled from the ground or from the crane cabin. The magnet strength control can be integrated as an optional function. This is convenient for lifting individual sheet metals.

Important parameters:

- Application: Lifting

- Technology: Electropermanent

- Nominal lifting capacity for flat material: up to 4000 kg

- Temperature: max. 80 °C

- Duty cycle: 100 %

- Safety factor: 3:1

- Guarantee: 2 years

Typical use:

- NEOSQ300 - handling smaller parts from mass production, blanks, forgings, castings

- NEOSQ600 - handling longer parts and profiled sections (steel strips, rails, tubes, beams, and rods) for subsequent material cutting by saw, e.g. in metallurgical warehouses.

- NEOSQ1000 - handling thicker sheets, burn parts, tools, and cuts. Suitable for large tables, where it is difficult to use e.g. Neo series permanent magnets.

- NEOSQ4000 - handling large parts during plasma cutting. The control panel is shifted to the edge for comfortable removal of the magnet from the machine table.

Scope of supply:

- Magnet

- Certificate

- Power supply cable

- Instructions for use

Parameters

| Model |

W (mm) |

L (mm) |

H (mm) |

Number of poles |

Pole structure |

Clamping surface (mm) |

Weight (kg) |

| NEOSQ300 |

164 |

164 |

420 |

4 |

50 x 50 |

116 x 116 |

23 |

| NEOSQ600 |

95 |

420 |

450 |

6 |

50 x 50 |

52 x 372 |

31 |

| NEOSQ1000 |

228 |

228 |

295 |

4 |

80 x 80 |

172 x 172 |

39 |

| NEOSQ4000 |

228 |

783 |

295 |

16 |

80 x 80 |

172 x 724 |

132 |