PERMANENT MAGNETIC CHUCKS

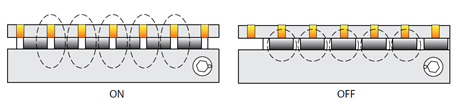

In permanent magnetic chucks, highly energised magnetic and ferromagnetic materials are used, which attract the magnetic steel when these are in a certain configuration. Magnets do not lose their magnetic force under normal conditions. Activation and deactivation (switching ON/OFF) is carried out mechanically, by removal of the interior system with permanent magnets. A manual lever is most commonly used for this action.

Advantages of permanent magnetic chucks

- No dependence on electric power, safe, and no combined expenses.

- Easy installation and quick removal of the chuck onto another machine.

- No heat generation and thermal deformation of the top plate, which allows very precise machining.

- Usually with a dense pole pitch: very suitable for small and extra-small components.

- Solid construction, virtually maintenance-free with a long life span.

- Relatively low purchase costs.

Limitations of permanent magnetic chucks

- Limitation of chuck size usually up to 600 x 300 mm in size.

- Often without the possibility to control the holding force.

- The mechanical system is less suitable for automated processes.

ELECTROMAGNETIC CHUCKS

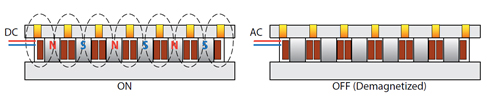

The magnetic field in this type of chuck is generated by coils through which a rectified current flows. There are ferromagnetic cores inside the coils. These cores are magnetized by the electric current. Electromagnets are activated by the control unit, which makes it possible to vary the force of the magnet and the demagnetization of the workpiece.

Advantages of electromagnetic chucks

- Easy operation thanks to the control unit; simply press the button or turn the switch.

- Magnetic holding force can be set up easily to create optimum conditions for attraction.

- Operation can be semi-automatic or automatic thanks to interconnection with the machine.

Limitations of electromagnetic chucks

- The magnet needs a continuous power supply, interruption leads to loss of holding force.

- With regard to application, an emergency power supply may be required.

- The current in the coils generates heat, which limits the accuracy.

ELECTROPERMANENT (EP) MAGNETIC CHUCKS

In reality, electropermanent magnetic chucks are permanent magnetic chucks. The permanent magnets inside the chuck are activated and deactivated by the magnetic field of the coils in which they are located. Electric current is only needed for a few seconds so as to create the magnetic field and magnetize or demagnetize the permanent magnets, or change their polarity. The control unit supplies the current, enabling selection of the holding force and demagnetization of the component.

Advantages of EP magnetic chucks

- Greater safety because the holding force is generated by permanent magnets and if the electric current is interrupted, the component remains firmly clamped.

- Minimum electricity consumption.

- Operation via the control unit makes it possible to set the holding force. Sometimes demagnetization and automatic operation during machining.

Limitations of EP magnetic chucks

- Higher purchase costs and sometimes higher weight compared to other types of magnet.

- In unfavourable conditions, EP magnets have a lower holding force for grinding than electromagnets.